Founded in 1999

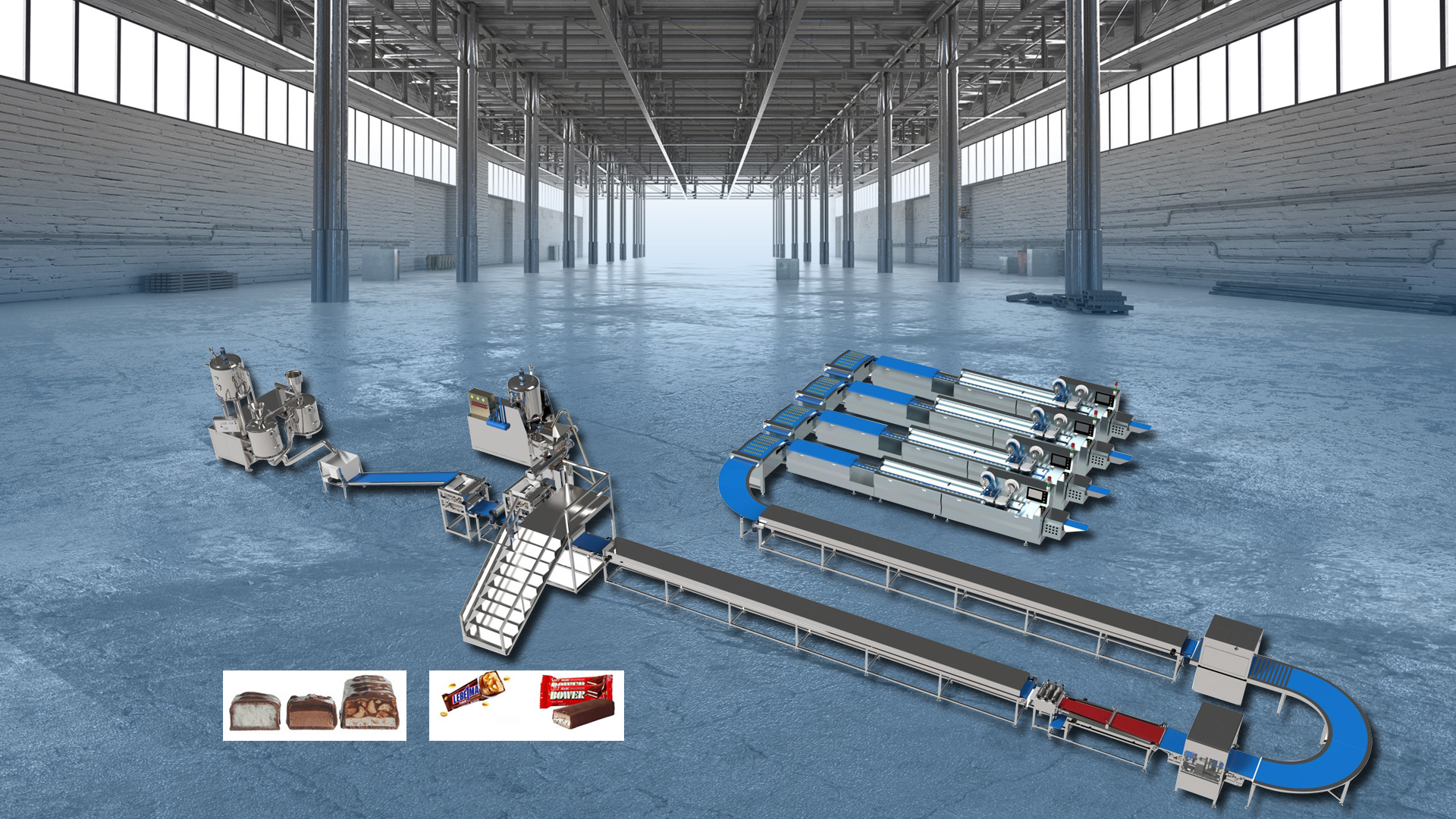

SINAITE FOODSTUFF MACHINERY

Company Profile

Our company specializes in the production of vacuum low temperature boiling aerated mixing equipment, milk sugar, nougat, Swiss sugar and other production line equipment and automatic packaging machinery and equipment: through continuous innovation and research and development, and perfect after-sales service, we have gathered a group of high-quality, rich practical experience in the food machinery industry, with super debugging equipment, and technical personnel to solve practical production problems, which have been highly praised by customers at home and abroad. The products are exported to South America, the Middle East, Southeast Asia, Africa and other regions. Snyder Food Machinery is actively committed to improving product quality and technological innovation. Warmly welcome customers at home and abroad to visit and provide valuable advice, so that we can do better and create brilliant tomorrow.

Founded in 2007

Area covered

Partner

News

The importance of cleaning the equipment of the gummy production line in time

It is very important to clean and sterilize food residues and microorganisms present in food production equipment and pipelines during the food production process. 1. Food safety Effective cleaning of food machinery can remove microorganisms and bacteria produced in production as much as possible, and eliminate the breeding sites of microorganisms, thereby eliminating the source of pollution in the food processing stage, reducing food pollution, and ensuring food hygiene and safety. 2. Food taste In the process of food production, the same equipment needs to produce different foods, which leads to the mixing of tastes and raw materials between different foods, which seriously affects the taste of food. Comprehensive cleaning of food production machinery can ensure that The pure taste of the food. 3. Equipment operation Prevent the mechanical corrosion of food caused by the interaction of food residues and metal parts, reduce the reduction of mechanical thermal conductivity and other properties caused by contamination coverage, so as to ensure the efficient operation of food production equipment and the superior food quality.

2022-09-27

Quality requirements for candy

The sensory quality of candy can be tested from its shape, appearance, color, aroma, taste and hardness. shape and appearance 1. The shape of the candy should be neat and correct, the size should be uniform, and there should be no bends, cracks and barbs. 2. The surface of the candy should be smooth and clean. For example, the surface of hard candy should be bright and white, and the thickness of the outer skin should be uniform. The filling is not exposed. 3. The wrapping paper should be clean. For candies without wrapping paper, such as those mixed with granulated sugar, the sand should be evenly attached; those without granulated sugar should have a smooth and bright surface. The color and luster of the candy should be bright and uniform, and there should be obvious color and luster to distinguish it from other varieties.

2022-09-27

The working principle of the sugar cooking machine

The purpose of boiling sugar is to remove most of the water in the sugar liquid after dissolving the sugar, so that the massecuite reaches a high concentration and retains less water, and the sugar liquid is turned into a viscous massecuite. It must be done by a boiling evaporation process with an elevated temperature gradient. This process is achieved through continuous boiling and processing, so it is called boiling sugar. The water in the sugar liquid needs to be removed from the liquid surface and into the space to be eliminated. The faster the separation speed, the faster the cooking speed. Under vacuum conditions, the sugar liquid can be boiled and evaporated at a lower temperature, the evaporation speed is fast, and the product quality is good. Operating procedures: The vacuum boiling process is generally divided into three stages: preheating, evaporation and vacuum concentration. In the preheating stage, the temperature and concentration of the sugar liquid are increased, and the period of vacuum boiling sugar is shortened; in the evaporation stage, the remaining water in the sugar liquid is removed. The sugar boiling equipment is actually a set of evaporation and concentration equipment. The function of the heater is to heat the sugar liquid to a boiling state with an appropriate heat source and sufficient heat transfer area. The evaporator can quickly remove water from the sugar liquid in the boiling state, and the transfer pump can stably transport the sugar liquid through the whole process to achieve continuous and balanced production.

2022-09-27