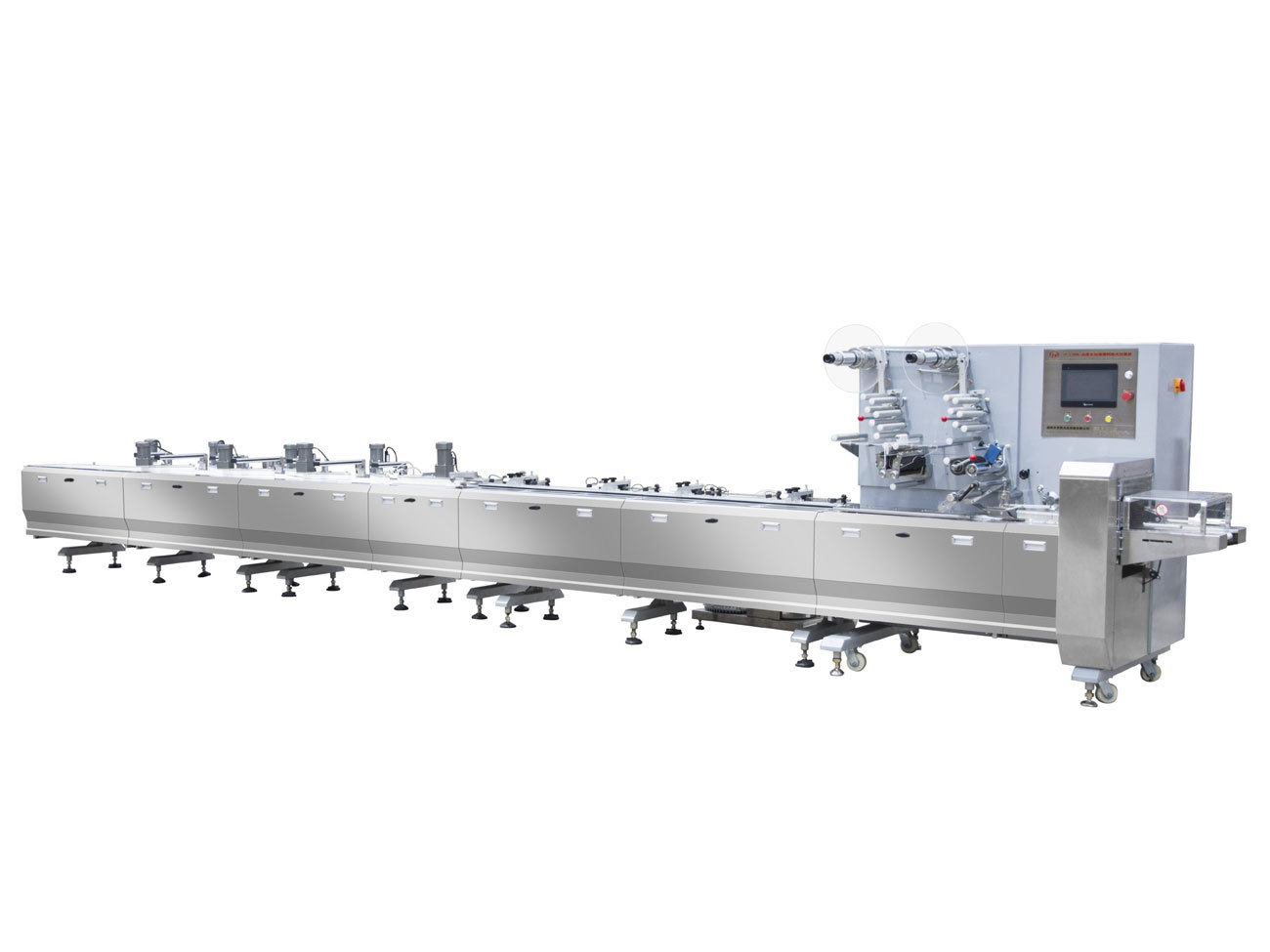

SNT-L1000 High speed full automatic feeding pillow packing machine

Summary: Production of vacuum low-temperature boiling aerated mixing equipment, production line equipment such as milk sugar, nougat, Swiss sugar, and automatic packaging machinery and equipment: Through continuous innovation, research and development, and perfect after-sales service, we have gathered a group of high-quality, rich practical experience in the food machinery industry, strong debugging equipment, and technical personnel to solve practical production problems. Our products are exported to South America, the Middle East, and Southeast Asia, In Africa and other regions, Snyder Food Machinery is actively committed to improving product quality and technological innovation.

Key Word: Packaging machine、Boiling system

key word:

Category:

Product Description

Characteristics

1、Advanced full servo control system and simple transmission construction,low maintenance and low noise;

2、It can be connected directly with the production line and make the products sending,forming.filling and sealing an full automation process.It improves the working efciency and reduce the cost.

3、The control system adopts high quality electronic parts.With touch screen and friendly machine-human interface,it is easy to operate and you can see the machine working processes clearly.

4、With paper splicer system and it can change the fim roller automatically without stop,which improves the working efciency.

5、The feeding belts don't need tools to release or install.There is wastage plate under the belts and it is easy for maintenance and clean and it saves time and labor.

6、With product-inspecting system and it helps to achieves the real no-empty package.The packing rate is 100%.

Production of vacuum low temperature boiling aerated mixing equipment, production line equipment such as milk sugar, nougat, Swiss sugar and automatic packaging machinery and equipment: through continuous innovation and research and development, and perfect after-sales service, a group of high-quality, rich practical experience in the food machinery industry, super debugging equipment, and technical personnel to solve practical production problems have been gathered, which has been unanimously praised by customers at home and abroad.

The products are exported to South America, the Middle East, Southeast Asia, Africa and other regions. Snyder Food Machinery is actively committed to improving product quality and technological innovation.

Related products

Product Consulting